Ever feel that slight shudder when you brake? Or perhaps a nagging worry that something's not quite right with your F350's stopping power? Well, you're not alone. For many F350 owners, understanding the intricacies of brake maintenance, especially those all-important caliper torque specs, can feel like navigating a maze. But don't worry, because today we're diving deep into the world of F350 caliper tightening procedures, offering a clear and comprehensive guide to ensure your truck stops on a dime, every time.

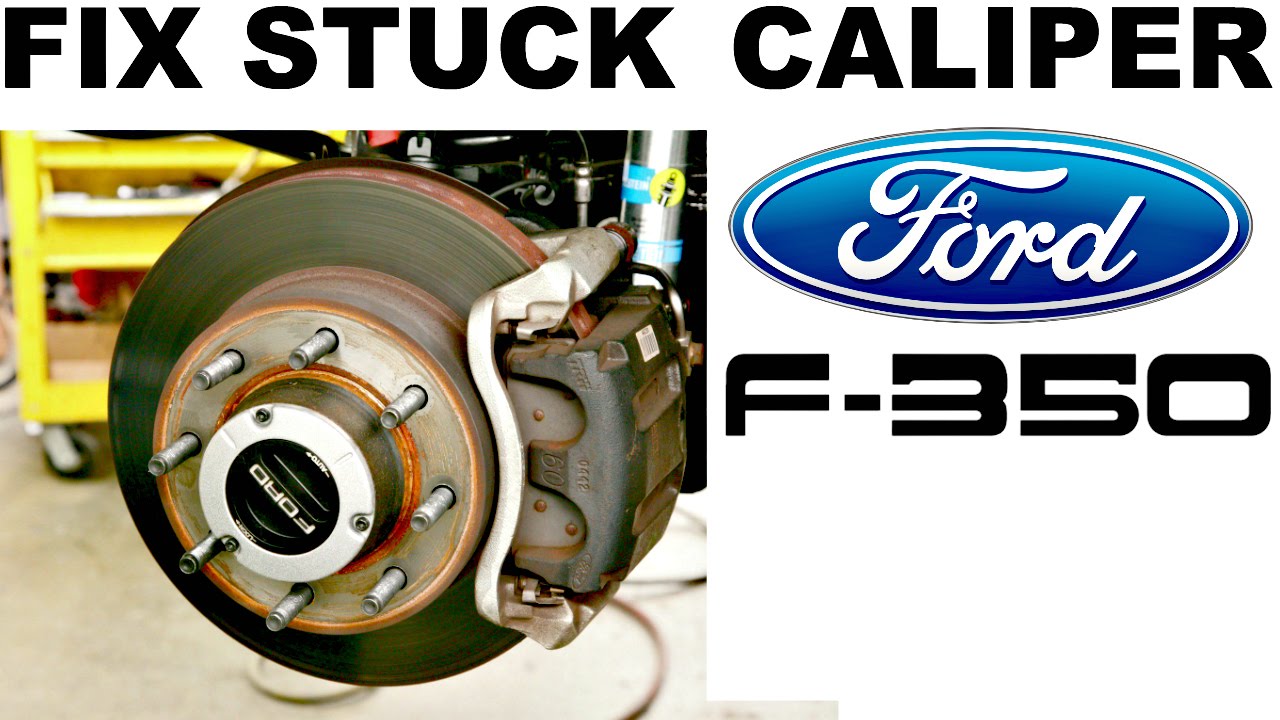

Understanding the correct F350 caliper torque specifications is paramount for safe and effective braking. These specs, essentially a precise measurement of how tightly the caliper bolts should be fastened, are crucial for preventing issues like uneven brake pad wear, warped rotors, and even caliper failure. Ignoring these specifications can lead to costly repairs and, more importantly, compromise your safety on the road.

While the specific torque values may vary slightly depending on the year and model of your F350, the underlying principle remains the same: precision is key. Over-tightening can strip the threads or damage the caliper, while under-tightening can lead to loosening and potential brake failure. Finding the “Goldilocks” torque – just right – is essential for maintaining a reliable braking system.

Historically, brake systems have evolved significantly, with the F350's robust design reflecting this progress. From drum brakes to the advanced disc brake systems we see today, the importance of proper caliper installation and torque specifications has remained constant. Ensuring proper torque application is a crucial step in maintaining the integrity and longevity of these complex systems.

The importance of correct F350 front and rear caliper torque specs cannot be overstated. These specifications, often found in your vehicle's repair manual or online resources, ensure that the calipers are securely mounted, allowing the brake pads to apply even pressure to the rotors. This precise application of force is what translates into smooth, controlled stops, preventing premature wear and tear on your brake components.

Benefits of adhering to the correct F350 caliper bolt torque specs include: enhanced safety through optimal braking performance, extended lifespan of brake components, and reduced risk of costly repairs. For instance, properly torqued calipers minimize the chance of warped rotors, a common issue that can lead to pulsating brakes and reduced stopping power.

A successful brake job on your F350 involves carefully following the torque specifications outlined in your vehicle's service manual. Using a calibrated torque wrench is essential for achieving the correct tightness. This precision tool allows you to apply the exact amount of force required, preventing over or under-tightening.

Finding reliable information about your F350's caliper torque specs is crucial. Consult your owner's manual or reputable online resources dedicated to F350 maintenance. Always double-check the information to ensure accuracy and compatibility with your specific model year.

Tips and tricks for working with F350 caliper torque specs include cleaning the caliper mounting surfaces before installation and applying a thin layer of anti-seize lubricant to the bolts. This prevents corrosion and ensures accurate torque readings. Always double-check your work and refer to your vehicle's service manual for specific torque values.

In conclusion, mastering the nuances of F350 caliper torque specs is essential for maintaining a safe and reliable braking system. By understanding the importance of these specifications and following proper procedures, you can ensure optimal braking performance, prevent costly repairs, and ultimately, enjoy peace of mind knowing your truck will stop when you need it to. Don't underestimate the power of proper maintenance – it's an investment in your safety and the longevity of your F350.

Boeing 747 400 seating configurations a comprehensive guide

Behr helium m480 1 a subtle shade with big impact

Find your dream west virginia cabin retreat