In the intricate world of electrical engineering, where currents flow and circuits hum, a silent language governs the safety and efficiency of our motorized systems. This language is expressed through symbols, cryptic to the uninitiated, yet vital for anyone working with motor protection. Among these symbols, the overload relay contact symbol holds a particular significance, acting as a sentinel against the damaging effects of excessive current.

Imagine a bustling factory floor, a symphony of whirring machines powered by electric motors. These motors, the heart of industrial processes, are susceptible to overheating and damage if subjected to prolonged overloads. Here, the overload relay, and its associated contact symbol, steps in, preventing catastrophic failures and ensuring the longevity of these essential components.

The overload relay contact symbol, a seemingly simple graphical representation, embodies a complex function within electrical circuits. It acts as a visual shorthand, conveying the operational logic of the overload relay to engineers and technicians. Understanding this symbol is crucial for interpreting circuit diagrams, troubleshooting electrical faults, and ensuring the safe operation of motor-driven equipment.

But how did this symbolic language evolve? The history of the overload relay contact symbol is intertwined with the development of electrical engineering itself. As motors became increasingly prevalent in industrial settings, the need for reliable protection mechanisms grew. Early overload relays were rudimentary devices, but their associated symbols laid the groundwork for the standardized representations we use today.

The standardization of overload relay contact symbols is a testament to the collaborative nature of engineering. Organizations like the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) have played a vital role in establishing consistent symbology, facilitating clear communication and interoperability across diverse industries and geographical regions. This standardization has undoubtedly contributed to improved safety and efficiency in electrical systems worldwide.

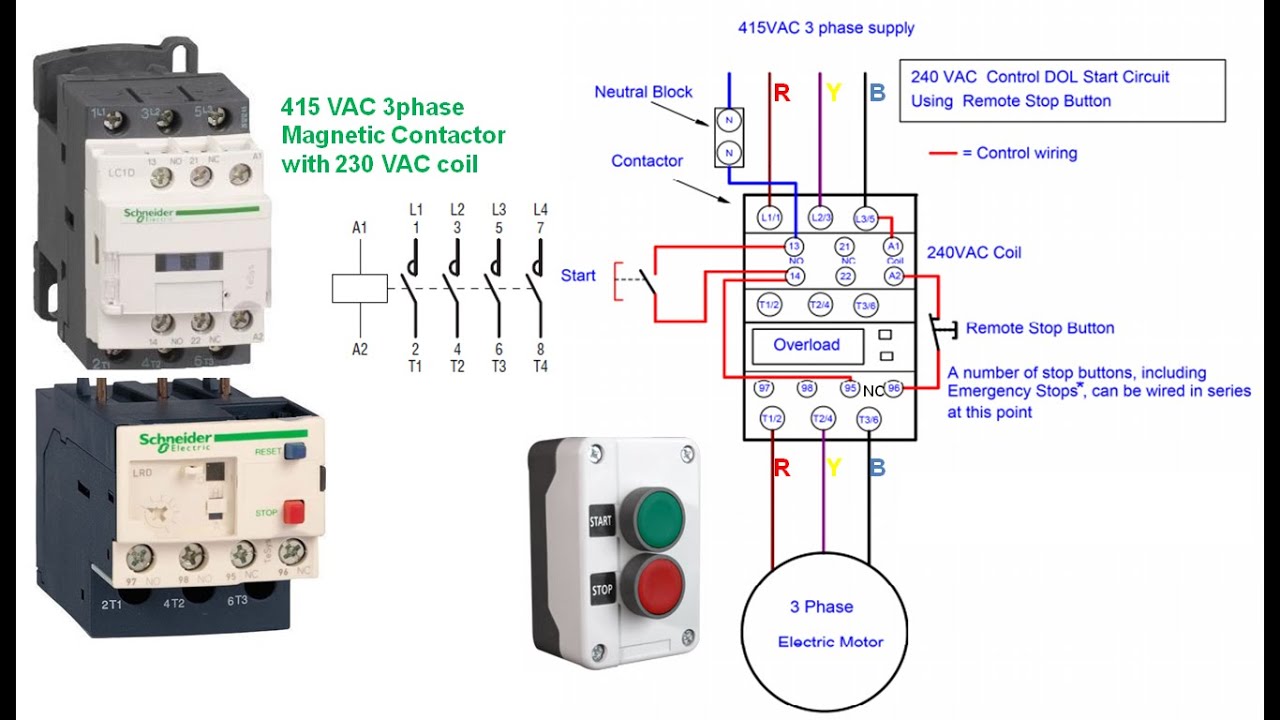

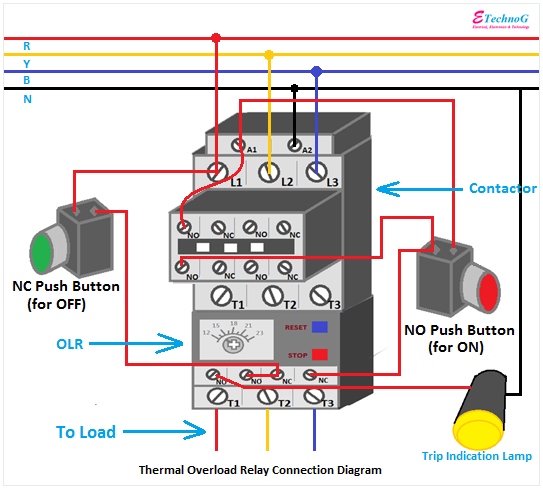

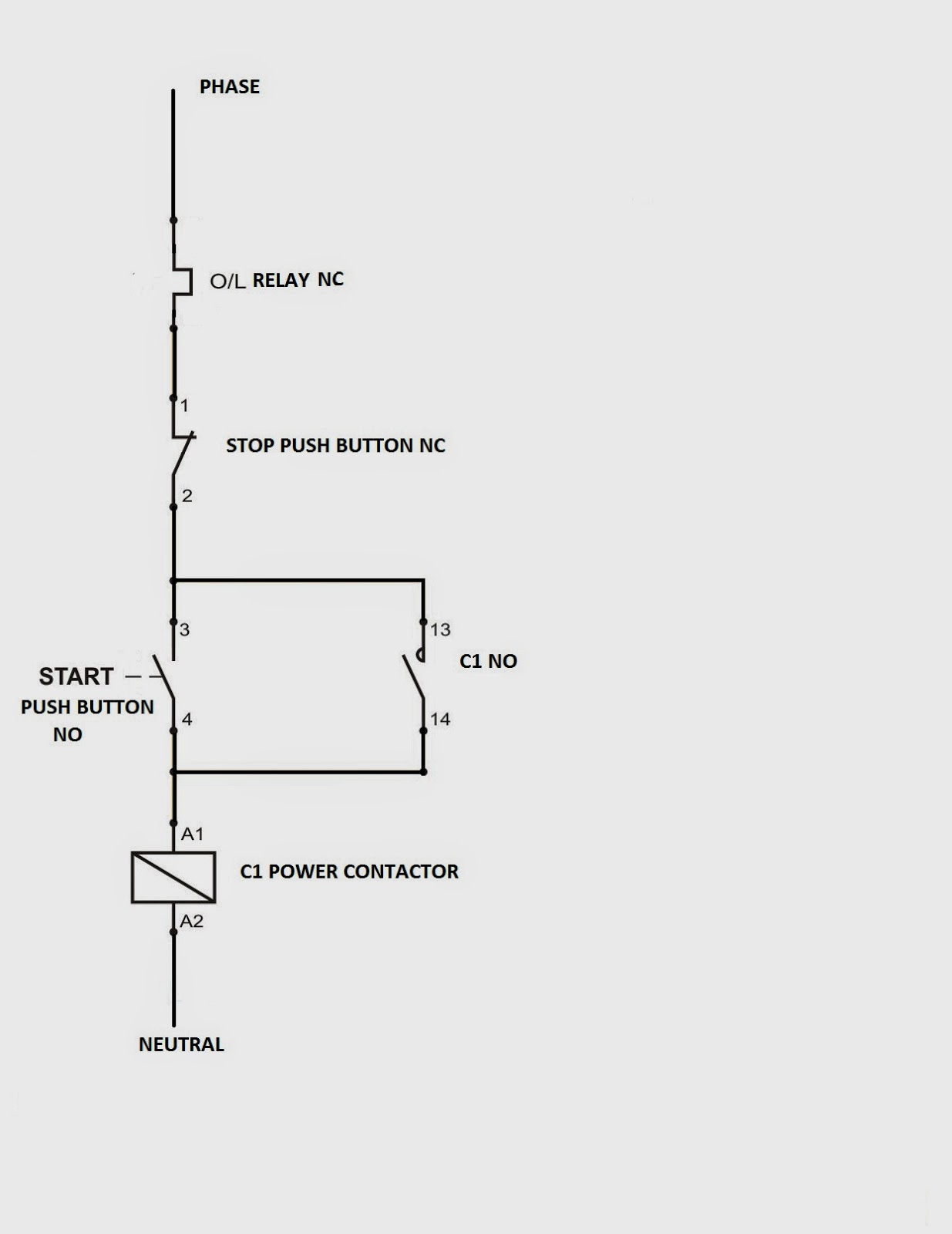

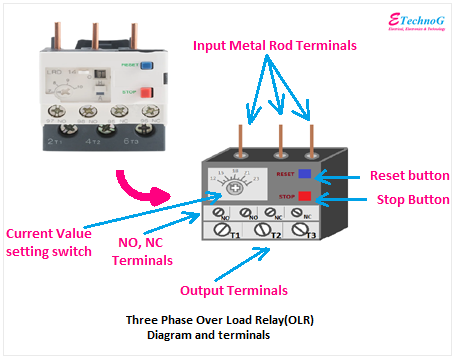

The overload relay functions as a critical safety device in motor control circuits. Its primary role is to protect the motor from damage due to excessive current. This excessive current can stem from various factors, such as mechanical overload on the driven equipment, a locked rotor, or a short circuit in the motor windings. The overload relay constantly monitors the current flowing to the motor. When this current exceeds a predetermined threshold for a specified time, the relay's contacts open, interrupting the power supply to the motor and preventing overheating. Understanding the representation of these "normally open" and "normally closed" contacts on schematic diagrams is facilitated by the overload relay contact symbol.

One benefit of using standardized overload relay contact symbols is the enhanced clarity in circuit diagrams. These symbols provide a concise and unambiguous representation of the overload relay's function and its interaction with other circuit components. This clarity simplifies troubleshooting and maintenance, allowing technicians to quickly identify and address potential issues.

Another advantage is improved safety. By using standardized symbols, engineers and technicians can ensure that the overload relay is correctly integrated into the motor control circuit, providing the necessary protection against overloads and short circuits. This reduces the risk of motor damage, fire hazards, and other safety concerns.

Furthermore, the standardized symbolism fosters efficient communication among electrical professionals. Regardless of their background or location, engineers can readily interpret circuit diagrams incorporating these symbols, promoting collaboration and seamless project execution.

Some best practices for implementing overload relays include selecting an overload relay with appropriate trip current rating, ensuring proper wiring connections according to the circuit diagram, periodically testing the relay's functionality, and regularly inspecting the relay for signs of wear or damage.

Advantages and Disadvantages of Standardized Overload Relay Contact Symbols

| Advantages | Disadvantages |

|---|---|

| Clear and concise representation | Requires familiarity with the standards |

| Improved safety | Potential for misinterpretation if standards are not followed strictly |

| Efficient communication | Variations in symbols between different standards |

Frequently Asked Questions:

1. What does the overload relay contact symbol represent? (It represents the switching action of the overload relay contacts.)

2. Why is standardization of overload relay symbols important? (For consistent interpretation and understanding.)

3. How does the overload relay protect a motor? (By interrupting the power supply in case of excessive current.)

In conclusion, the overload relay contact symbol, a seemingly small element in the vast landscape of electrical engineering, plays a crucial role in ensuring the safety and reliability of our motor-driven systems. Its standardized representation facilitates clear communication, enhances troubleshooting efficiency, and promotes best practices in motor protection. Understanding this symbol and its underlying principles empowers engineers and technicians to safeguard electrical equipment and maintain the smooth operation of industrial processes. By embracing these standards and continually seeking knowledge in the ever-evolving field of electrical engineering, we can collectively contribute to a safer and more efficient electrified world.

Boat fresh water pump pressure switch secrets

Unlocking the magic of sherwin williams la luna amarilla

Unlocking the power of sw 0055 light french gray