Is your Gem boat lift giving you trouble? A malfunctioning boat lift can quickly turn a relaxing day on the water into a frustrating ordeal. This guide aims to demystify the process of diagnosing and resolving issues with your Gem boat lift, empowering you to keep your boat secure and ready for adventure.

Maintaining a boat lift is crucial for protecting your valuable investment. A well-maintained lift not only ensures the safety of your boat but also extends its lifespan. Gem boat lifts, known for their quality and durability, still require regular care and occasional troubleshooting. This guide will equip you with the knowledge and resources you need to effectively address Gem boat lift problems.

The origins of boat lifts can be traced back to simple, hand-cranked devices used to haul boats ashore. Over time, these evolved into the sophisticated electric and hydraulic systems we see today, like the Gem boat lift. The need for effective Gem boat lift troubleshooting arose alongside this technological advancement. As boat lifts became more complex, understanding their workings and addressing potential problems became increasingly important.

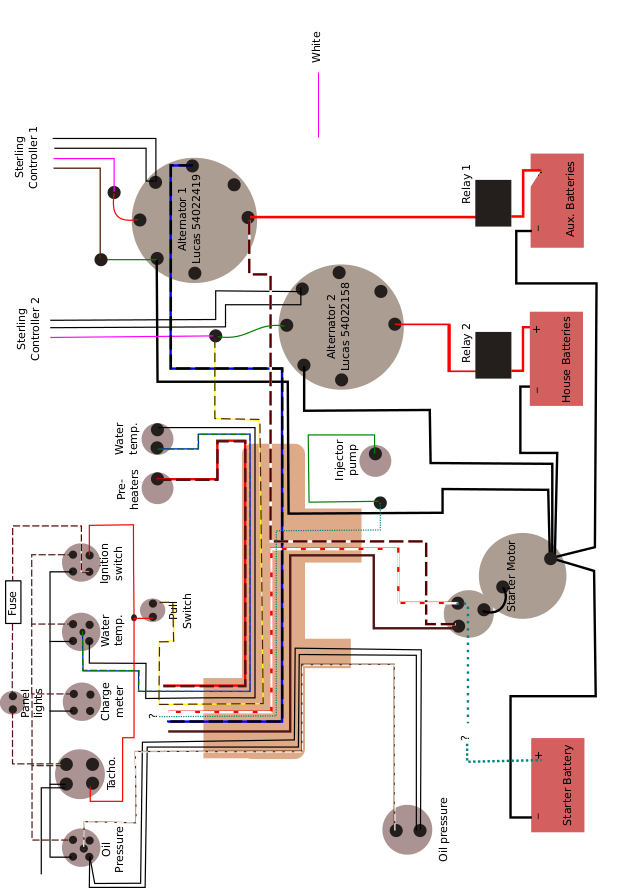

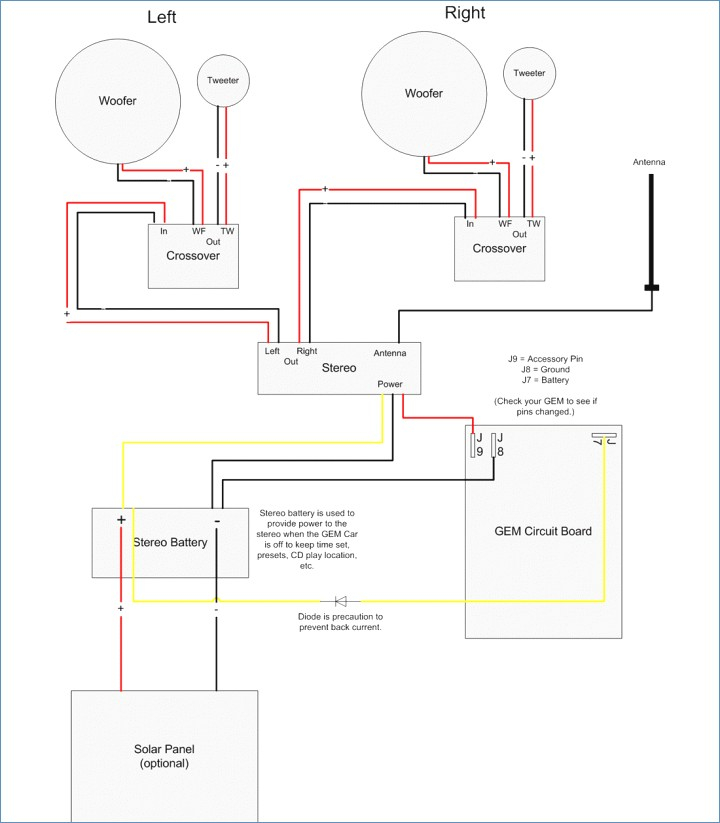

Among the most common Gem boat lift issues are motor malfunctions, cable problems, and electrical faults. Motor problems can range from worn-out brushes to complete motor failure. Cable issues often involve fraying, stretching, or improper winding. Electrical problems can stem from faulty wiring, corroded connections, or issues with the control box. This guide will delve into each of these areas, providing practical solutions and preventive measures.

Understanding the different components of your Gem boat lift is essential for effective troubleshooting. The motor provides the power to raise and lower the lift. Cables transmit this power to the cradle, which holds your boat. The control box manages the lift's operation, allowing you to control its movement. Knowing how these parts interact will help you pinpoint the source of any problem.

One benefit of regular Gem boat lift maintenance and troubleshooting is increased safety. By addressing potential issues early on, you can prevent accidents and ensure the secure storage of your boat. Regular inspection can also prevent costly repairs down the line. Finally, proactive maintenance enhances the longevity of your lift, maximizing your investment.

A simple troubleshooting action plan involves visually inspecting the lift, checking the electrical connections, and testing the motor. For instance, if your lift isn't moving, check the circuit breaker and ensure the power cord is properly connected. If the motor runs but the lift doesn't move, inspect the cables for damage or slippage.

Advantages and Disadvantages of DIY Gem Boat Lift Troubleshooting

| Advantages | Disadvantages |

|---|---|

| Cost savings | Potential for further damage if not done correctly |

| Immediate attention to minor issues | Risk of injury |

Best practice for troubleshooting is to always disconnect the power before working on the lift. Another is to consult the owner's manual for specific instructions related to your model. Keep a log of maintenance and repairs. Regularly lubricate moving parts. Finally, if you're unsure about anything, consult a qualified Gem boat lift technician.

Frequently Asked Questions:

1. Why is my Gem boat lift not working? (Check power supply, cables, and motor.)

2. How often should I inspect my boat lift? (At least monthly, more frequently in harsh conditions.)

3. What type of lubricant should I use? (Refer to your owner's manual for specific recommendations.)

4. Can I replace the cables myself? (It's recommended to consult a professional.)

5. How do I reset the control box? (Consult your owner's manual.)

6. What causes a boat lift motor to burn out? (Overloading, lack of lubrication, electrical issues.)

7. How can I prevent cable fraying? (Regular inspection and lubrication.)

8. Where can I find replacement parts for my Gem boat lift? (Authorized Gem dealers or online retailers.)

Tips and Tricks: Keep a spare set of shear pins on hand. Use a cable tension gauge to ensure proper cable tension. Document any unusual noises or vibrations. Label all electrical connections.

In conclusion, understanding the basics of Gem boat lift troubleshooting can save you time, money, and frustration. By implementing the best practices outlined in this guide, you can keep your boat lift operating smoothly for years to come. Regular maintenance, coupled with prompt attention to potential problems, is key to ensuring the safety and longevity of your lift. Remember to consult your owner’s manual for specific instructions related to your model and don’t hesitate to seek professional help when needed. Taking proactive steps to maintain your Gem boat lift is an investment in your peace of mind and the enjoyment of your time on the water. Don’t wait until a small problem becomes a major headache – start implementing these strategies today and ensure your boat lift remains a reliable asset for years to come. By being proactive and informed, you can enjoy countless hours of worry-free boating.

Humana medicare advantage plan comparison

Big sleeps tattoo lettering a deep dive into typography and ink

Exploring the trend of dark aesthetic anime boy profile pictures