There's a quiet satisfaction in mastering the mechanics of waterfront living. Like a perfectly tailored nautical blazer, a smoothly operating boat lift is essential. And sometimes, just like a worn button or frayed cuff, that smooth operation requires a bit of maintenance – specifically, knowing how to replace a boat lift motor.

The gentle hum of a well-functioning boat lift is a familiar sound along the docks. But when that hum falters, or worse, grinds to a halt, it's time to address the heart of the system: the motor. Replacing a boat lift motor might seem daunting, but with a bit of guidance, it becomes a manageable task, returning that quiet confidence to your waterfront routine.

Boat lifts themselves have evolved from simple hand-cranked systems to the powerful, electric models we see today. This evolution reflects the increasing size and weight of boats, demanding more robust lifting mechanisms. The electric motor became a pivotal component, enabling effortless raising and lowering of substantial vessels. This evolution underscores the importance of understanding motor replacement – it's a skill essential for maintaining the functionality of modern boating equipment.

The most common issue requiring a boat lift motor replacement is, simply, motor failure. This can manifest in various ways: a humming motor that doesn't lift, a grinding noise indicating gear wear, or a complete lack of response. Troubleshooting these problems often leads to the conclusion that replacement is the most efficient and cost-effective solution. Other factors like corrosion due to the marine environment can also contribute to motor wear and tear.

Before diving into the actual replacement process, it's crucial to identify the correct replacement motor. Consult your boat lift's documentation or contact the manufacturer to determine the specific model and specifications required. Using the wrong motor can lead to further complications and potentially damage the lift system. This step is as crucial as selecting the right fabric for a bespoke suit – the details matter.

One of the key benefits of learning how to replace your boat lift motor is cost savings. Hiring a professional can be expensive. Doing it yourself empowers you to take control of the maintenance process and save significantly on labor costs. It also provides the satisfaction of knowing your equipment is in good hands – your own.

Another advantage is the convenience. Waiting for a technician to become available can disrupt your boating schedule. Being able to replace the motor yourself means you can address the issue promptly and get back on the water without delay. It's the equivalent of having a well-stocked sewing kit on hand – you can handle minor repairs quickly and efficiently.

Finally, understanding boat lift motor replacement gives you a deeper understanding of your equipment. This knowledge translates to better preventative maintenance and a longer lifespan for your boat lift. Just as knowing the intricacies of a garment's construction allows for better care, understanding your boat lift’s mechanics leads to more effective maintenance.

Replacing the Boat Lift Motor: A Step-by-Step Guide

1. Disconnect power to the boat lift.

2. Secure the boat lift in the raised position.

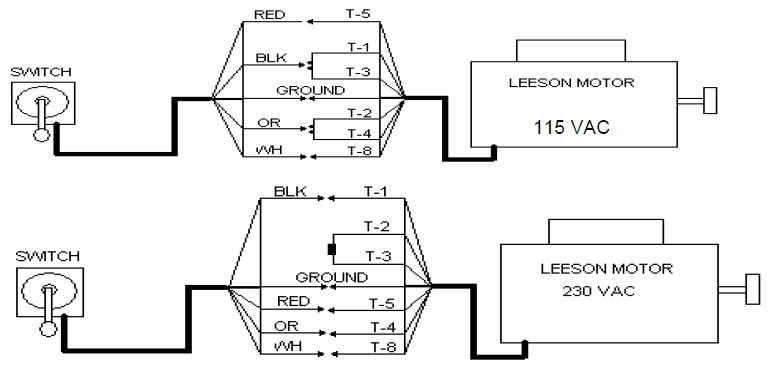

3. Remove the old motor’s wiring connections, carefully labeling each wire.

4. Detach the old motor from the lift mechanism.

5. Install the new motor, ensuring proper alignment and secure mounting.

6. Connect the wiring to the new motor, matching the labels from the old motor.

7. Test the new motor by briefly powering on the lift (with the boat still secured).

8. Lower the boat lift slowly and check for smooth operation.

Advantages and Disadvantages of DIY Boat Lift Motor Replacement

| Advantages | Disadvantages |

|---|---|

| Cost Savings | Potential for Errors |

| Convenience | Requires Tools and Knowledge |

| Increased Equipment Knowledge | Safety Risks if Improperly Done |

Frequently Asked Questions

Q: How often should I replace my boat lift motor?

A: Motor lifespan varies, but regular maintenance can extend its life. Replacement is typically necessary when the motor fails or shows signs of significant wear.

Q: Can I use any motor as a replacement?

A: No, use the correct model and specifications for your boat lift.

Q: What tools do I need?

A: Basic hand tools like wrenches, screwdrivers, and possibly a socket set.

Q: Is it safe to do this myself?

A: Yes, with proper precautions and by following safety guidelines.

Q: What if I encounter problems during the replacement process?

A: Consult your boat lift’s documentation or contact the manufacturer for assistance.

Q: How can I prevent future motor issues?

A: Regular maintenance, including lubrication and inspection, can help prevent premature motor failure.

Q: Where can I purchase a replacement motor?

A: Marine supply stores, boat lift dealers, or online retailers.

Q: What are the signs of a failing boat lift motor?

A: Grinding noises, slow lifting, or a humming motor that doesn't lift the boat.

In conclusion, replacing a boat lift motor can seem like a significant undertaking. However, by breaking down the process into manageable steps and armed with the right information, it becomes a task within the grasp of any dedicated boat owner. The benefits of DIY replacement – cost savings, convenience, and increased equipment knowledge – far outweigh the initial apprehension. Just like a perfectly executed stitch or a well-chosen accessory, a properly functioning boat lift contributes to the seamless enjoyment of waterfront living. Embracing this skill empowers you to maintain your equipment efficiently and ensures that your boat is always ready for the next adventure. So, gather your tools, consult your resources, and take pride in mastering this essential aspect of boat ownership. The quiet hum of your newly installed motor will be a testament to your efforts and a welcome soundtrack to your waterfront lifestyle.

Unlocking nfl playoff glory your guide to predictions

G80 m3 m performance front lip the ultimate guide

Dead car battery amazon jump box batteries to the rescue