Ever felt that pang of frustration when a seemingly perfect wheel just won't fit your ride? A crucial aspect of wheel compatibility often overlooked is the bolt pattern. Getting this right is paramount for safety and performance. This comprehensive guide will equip you with the knowledge to confidently measure a 4/110 bolt pattern, ensuring a smooth and secure fit.

The 4/110 bolt pattern, also denoted as 4x110, refers to the arrangement of the lug holes on a wheel. The "4" signifies four lug holes, while "110" represents the diameter of the circle formed by the center of these holes, measured in millimeters. Understanding this seemingly small detail is a giant leap towards a successful wheel upgrade.

Historically, bolt patterns evolved alongside the automotive industry itself, varying based on manufacturer and vehicle type. The 4/110 pattern is commonly found on smaller vehicles like ATVs, go-karts, and some smaller trailers. Accurately determining this pattern prevents costly mistakes and ensures compatibility, contributing to safe and efficient vehicle operation. A mismatched bolt pattern can lead to vibrations, premature wear, and even wheel detachment – a recipe for disaster.

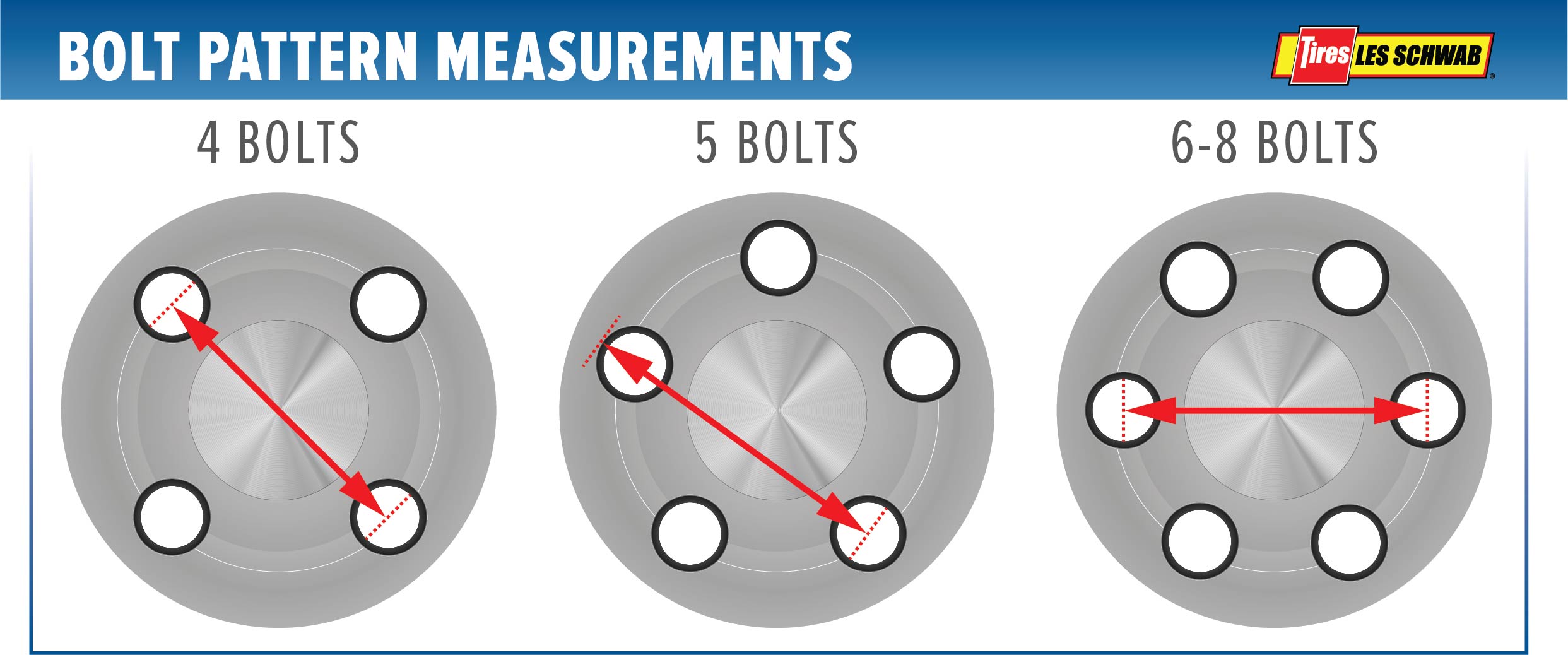

Measuring a 4/110 bolt pattern is surprisingly straightforward. For wheels with four lug holes, measure from the center of one lug hole directly across to the center of the opposite lug hole. This measurement should be 110mm for a 4/110 pattern. However, some measurements might require slightly more finesse. If you're dealing with an odd number of lug holes, the direct opposite measurement isn't possible. Don't worry; we'll cover that too!

Before diving into the practical steps, let's equip ourselves with a clear understanding of the key terms. The "pitch circle diameter" (PCD) is the crucial measurement here, representing the diameter of the imaginary circle passing through the center of all lug holes. In our case, the PCD is 110mm. Understanding this term is fundamental to grasping the entire process.

One benefit of accurate 4/110 bolt pattern measurement is avoiding costly returns and exchanges. Imagine the hassle of ordering wheels only to discover they don't fit! Measuring beforehand eliminates this frustration. Secondly, correct fitment ensures safety and prevents potential accidents caused by loose or detached wheels. Lastly, a proper fit maximizes performance, preventing vibrations and ensuring optimal handling.

To accurately determine if a wheel has a 4/110 bolt pattern, use a caliper or ruler to measure directly across the center of two opposite lug holes. For wheels with an odd number of lugs, measure from the back of one lug hole to the furthest point on the opposite side and use a bolt pattern chart or calculator to determine the PCD.

Best Practices:

1. Use a precise measuring tool like a digital caliper.

2. Double-check your measurements.

3. Refer to a reliable bolt pattern chart for verification.

4. Consult with a wheel specialist if unsure.

5. Never assume compatibility based on visual inspection alone.

FAQs:

1. What if my measurement isn't exactly 110mm? Slight variations can occur; consult a bolt pattern chart.

2. Can I use a tape measure? A caliper is preferred for accuracy.

3. What if my wheel has a different bolt pattern? You'll need to find wheels with a matching pattern.

4. Where can I find a bolt pattern chart? Online resources and automotive forums offer these charts.

5. Is the 4/110 pattern common? It's prevalent on certain ATVs, go-karts, and trailers.

6. What are the risks of using the wrong bolt pattern? Vibrations, premature wear, and potential wheel detachment.

7. Can I modify my vehicle's bolt pattern? It's generally not recommended and requires professional expertise.

8. Should I consult a professional? If unsure, it's always best to seek expert advice.

Tips and Tricks: Use a digital caliper for precise measurements. Clean the mounting surface of the wheel hub before measuring. If you're unsure, consult a wheel specialist.

Mastering the art of measuring a 4/110 bolt pattern empowers you to choose the right wheels for your vehicle confidently. This seemingly small detail plays a significant role in safety, performance, and overall driving experience. By understanding the basics, following the outlined steps, and adhering to best practices, you'll avoid the pitfalls of incompatible wheels and enjoy a smooth, secure, and stylish ride. Don't underestimate the importance of accurate measurements. Take the time to measure correctly, and you'll be rewarded with a perfect fit and peace of mind. Investing in the right tools and knowledge will save you time, money, and potential headaches down the road. Remember, a properly fitted wheel is a safe wheel, and safety should always be a top priority.

Yuji pfp and your to do list a powerful productivity duo

Unlocking the secret of covergirl classic ivory undertone

Unlock your inner wordsmith with writers parchment behr paint

.jpg)