Ever wondered how tight is *too* tight when fastening bolts? For engineers, mechanics, and even DIY enthusiasts, understanding proper bolt tightening is crucial. Over-tightening can lead to stripped threads or even broken bolts, while under-tightening can cause dangerous joint failures. This is where the grade 8.8 bolt torque specification comes into play, providing a roadmap to secure and reliable connections.

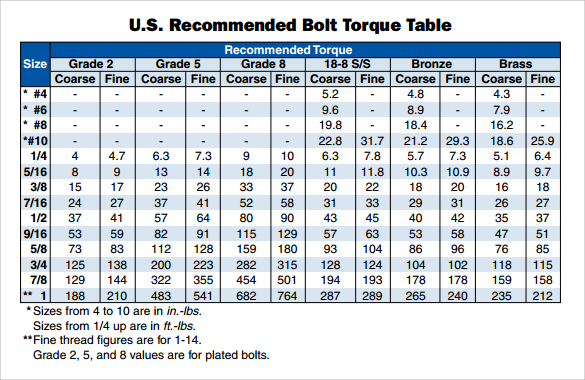

A grade 8.8 bolt torque chart, often available as a handy PDF, is a vital tool for anyone working with these common medium-strength fasteners. These charts typically list recommended torque values based on bolt size and whether the threads are lubricated or dry. Think of it as your cheat sheet for achieving the perfect clamping force – the pressure that holds the bolted joint together.

The importance of accurate torque specifications can’t be overstated. Incorrectly tightened bolts can compromise the integrity of structures, machinery, and even everyday objects. Imagine a bridge with loosely fastened bolts, or a car engine with improperly torqued head bolts – the consequences could be disastrous. That's why referencing a grade 8.8 bolt torque reference is paramount.

While the specific origin of standardized bolt torque charts is difficult to pinpoint, their development is intrinsically linked to the rise of industrial manufacturing and the need for consistent, reliable fastening methods. As engineering and material science advanced, so too did the understanding of bolt behavior under tension and the importance of precise torque control. This led to the development of standardized torque specifications like those found in a grade 8.8 bolt torque table.

One of the main issues surrounding bolt torque charts is ensuring you have the correct chart for the specific bolt grade you are using. Using a grade 8.8 chart for a different grade bolt could lead to incorrect tightening, potentially resulting in joint failure. It’s crucial to double-check the markings on your bolts and refer to the appropriate documentation. Another challenge is understanding the difference between dry and lubricated torque values. Lubrication significantly reduces friction, allowing for higher clamping force with the same applied torque. Using the wrong value can lead to over-tightening.

A grade 8.8 bolt denotes a specific strength class of metric fasteners. The "8.8" marking indicates a minimum tensile strength of 800 MPa and a yield strength of 640 MPa (80% of the tensile strength). These bolts are commonly used in various applications, from automotive and construction to general engineering.

Benefits of using a torque specification chart include: preventing joint failure, extending the lifespan of bolted connections, and ensuring consistent clamping force across multiple joints. For instance, in automotive applications, properly torqued wheel lug nuts prevent wheels from coming loose, ensuring safe operation.

To use a grade 8.8 bolt torque chart effectively, first identify the bolt size (diameter and thread pitch) and whether lubrication is being used. Then, locate the corresponding torque value in the chart. Use a calibrated torque wrench to apply the specified torque to the bolt.

Best practices include: using a calibrated torque wrench, cleaning bolt threads and lubrication surfaces, and tightening bolts in a cross pattern for even clamping force distribution.

Advantages and Disadvantages of Using a Torque Chart

| Advantages | Disadvantages |

|---|---|

| Prevents over-tightening and under-tightening | Requires accurate identification of bolt grade and size |

| Ensures consistent clamping force | Different charts may exist with varying recommendations |

| Enhances safety and reliability | Doesn't account for unique application-specific factors |

Frequently Asked Questions: What is a grade 8.8 bolt? What is torque? Why is proper torque important? Where can I find a grade 8.8 bolt torque chart? What's the difference between dry and lubricated torque? What is clamping force? What is a torque wrench? How do I use a torque wrench?

General Answers: These questions relate to the fundamental concepts of bolt strength, torque, and proper fastening techniques. Answers can be readily found online or in engineering handbooks.

Tips: Always double-check the bolt grade. Use a calibrated torque wrench. Consult the manufacturer's recommendations for specific applications. Store torque charts in a readily accessible location.

In conclusion, understanding and applying the correct torque specifications, often found in a grade 8.8 bolt torque specification document, is paramount for achieving secure and reliable bolted connections. Whether you're a seasoned engineer or a weekend DIY warrior, referencing a reliable torque chart is crucial for preventing joint failure, extending the lifespan of bolted assemblies, and ultimately, ensuring safety. Proper torque control isn't just about tightening bolts – it's about building with confidence. Invest the time to find and understand the appropriate torque specifications for your project; the peace of mind is well worth the effort. By following the best practices outlined above and staying informed about the latest information, you can ensure the integrity and longevity of your projects. Don't underestimate the power of a properly tightened bolt!

Finding renewal exploring whatcom countys treatment landscape

Electrify your ride the ultimate guide to scoring a used hybrid toyota rav4

Unlock culinary camping adventures essential cook utensils