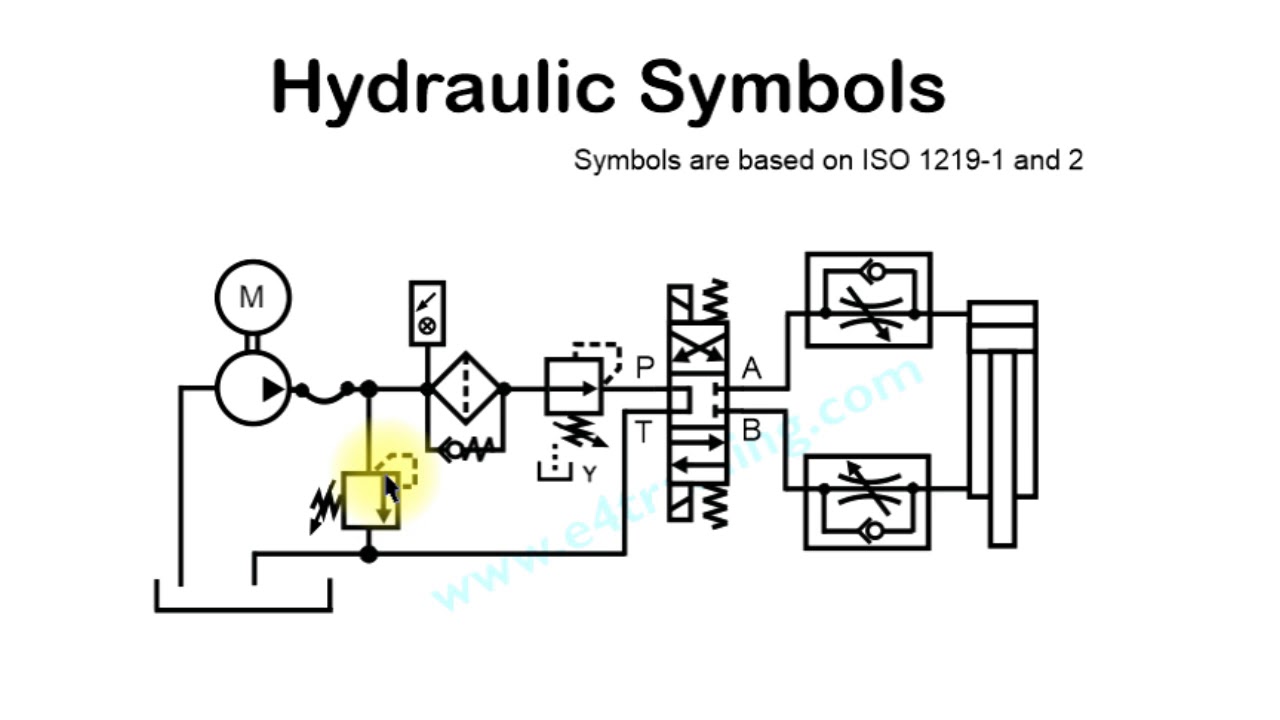

Imagine a complex network of pipes, valves, and actuators working together to power heavy machinery. How do you decipher the intricate workings of this system? The answer lies in understanding hydraulic symbols and their meanings. These standardized representations form the language of hydraulic schematics, providing a visual roadmap for anyone working with fluid power systems. Whether you're an engineer designing a new hydraulic circuit or a technician troubleshooting a malfunctioning system, a grasp of these symbols is crucial for effective communication and problem-solving.

Hydraulic symbols are more than just simple drawings; they are a precise and efficient way to communicate complex information. They provide a universal language that transcends geographical boundaries and language barriers. This standardized visual representation allows engineers and technicians worldwide to understand and work with hydraulic systems regardless of their background or native tongue. This consistency is paramount for ensuring safety, efficiency, and effective collaboration in the design, operation, and maintenance of hydraulic equipment.

The history of hydraulic symbols is intertwined with the development of hydraulic technology itself. As hydraulic systems became more sophisticated, the need for a standardized system of representation grew. Early hydraulic diagrams were often crude and inconsistent, leading to confusion and misinterpretations. Over time, organizations like the International Organization for Standardization (ISO) developed standardized symbol sets to ensure clarity and consistency across the industry. This standardization has been crucial for the advancement of hydraulic technology and its widespread application across various industries.

The importance of correctly interpreting hydraulic symbols and their meanings cannot be overstated. Misinterpreting a single symbol can lead to costly mistakes in system design, installation, or maintenance. Imagine a technician misidentifying a pressure relief valve on a hydraulic schematic. This could lead to improper adjustments, potentially resulting in system failure or even personal injury. Therefore, a thorough understanding of hydraulic symbology is essential for safe and efficient operation of hydraulic systems.

One of the main challenges associated with hydraulic symbols is the sheer number and variety of symbols used. From basic components like pumps and cylinders to more complex elements like directional control valves and accumulators, there are hundreds of symbols to learn and understand. Keeping up with the latest standards and interpretations can also be a challenge, requiring continuous learning and professional development. However, the benefits of mastering these symbols far outweigh the effort required to learn them.

A simple example is the symbol for a hydraulic pump. It typically resembles a circle with an arrow pointing outwards, indicating the flow direction. A hydraulic cylinder is represented by a rectangle with a piston rod extending from one end. Understanding these basic symbols is the first step towards interpreting more complex hydraulic diagrams.

One benefit of standardized hydraulic symbols is improved communication. Engineers can easily share designs and collaborate on projects without ambiguity. Another benefit is enhanced troubleshooting. Technicians can quickly identify components and understand their function within the system, allowing for faster and more accurate diagnosis of problems. Finally, standardized symbols contribute to increased safety by ensuring that everyone working with a hydraulic system understands its operation and potential hazards.

An action plan for learning hydraulic symbols might involve studying ISO standards, using interactive online resources, and practicing reading and interpreting hydraulic schematics. Successful implementation involves consistently applying learned symbols in real-world scenarios.

Advantages and Disadvantages of Standardized Hydraulic Symbols

| Advantages | Disadvantages |

|---|---|

| Improved Communication | Initial Learning Curve |

| Enhanced Troubleshooting | Keeping Up with Standards |

| Increased Safety | Potential for Misinterpretation if not properly trained |

Frequently Asked Questions:

Q: Where can I find a comprehensive list of hydraulic symbols? A: ISO standards and online resources offer detailed symbol libraries.

Q: How often are hydraulic symbols updated? A: ISO standards are periodically reviewed and updated to reflect technological advancements.

Q: Are there different symbol standards for different industries? A: While ISO standards are widely adopted, some industries may have specific variations or additions.

Q: What are the basic hydraulic symbols I should know? A: Start with symbols for pumps, cylinders, valves, and lines.

Q: How can I improve my ability to interpret hydraulic schematics? A: Practice reading and analyzing different diagrams, and consult with experienced professionals.

Q: What are some common mistakes when interpreting hydraulic symbols? A: Misinterpreting flow direction, valve function, or component type are common errors.

Q: Are there software tools that can help with hydraulic symbol interpretation? A: Yes, several CAD and simulation software programs offer libraries and tools for working with hydraulic schematics.

Q: What resources are available for learning more about hydraulic symbols and meanings? A: Textbooks, online tutorials, and industry training programs offer valuable learning opportunities.

Tips and tricks for working with hydraulic symbols include using color-coding to differentiate between different fluid types, clearly labeling components, and maintaining a consistent symbol library. Regularly reviewing and updating your knowledge of hydraulic symbols is crucial for staying proficient in this field.

In conclusion, hydraulic symbols and their meanings are the cornerstone of understanding and working with hydraulic systems. From design and installation to maintenance and troubleshooting, these standardized representations provide a crucial language for effective communication and collaboration. By mastering hydraulic symbology, engineers and technicians can ensure the safe, efficient, and reliable operation of hydraulic equipment across diverse industries. This understanding is not merely a technical skill; it is a fundamental requirement for anyone involved in the world of fluid power. Continue to explore resources, practice reading schematics, and stay updated with the latest standards to fully unlock the power of hydraulics. The ability to interpret hydraulic symbols is an investment in your professional development and a key to success in the field of hydraulic engineering and technology. Take advantage of the numerous resources available, both online and offline, and dedicate yourself to mastering this essential skill. It's an investment that will pay dividends throughout your career.

Decoding the title 38 hybrid pay system

Unlocking deep sound exploring the 10 inch wet sounds amplifier

Unlocking the victorias secret fit your guide to lingerie confidence