Ever wonder how your thermos keeps your coffee hot or how those fancy lab instruments work? The answer often lies in a simple yet powerful device: the vacuum pump. Understanding a vacuum pump work diagram is key to grasping its applications, from everyday objects to complex scientific equipment. Let's unravel the mysteries behind these ingenious inventions.

Imagine a space devoid of matter, essentially nothing. That’s a perfect vacuum, and while achieving it perfectly is nearly impossible, vacuum pumps get us pretty close. A vacuum pump schematic illustrates the process of removing air and other gases from a sealed container to create this low-pressure environment. This principle underlies a vast range of technologies we rely on daily.

The vacuum pump’s story begins centuries ago with Otto von Guericke's famous Magdeburg hemispheres experiment, demonstrating the power of atmospheric pressure. This spurred further development, leading to the invention of the first practical pumps. Today, understanding vacuum pump operation diagrams is essential in fields like medicine, manufacturing, and scientific research. From food packaging to space exploration, the applications are incredibly diverse.

Interpreting a vacuum pump diagram is crucial for troubleshooting and maintenance. Common issues like leaks or worn seals can hinder performance. By understanding the interplay of components, you can quickly identify and address potential problems, ensuring optimal efficiency.

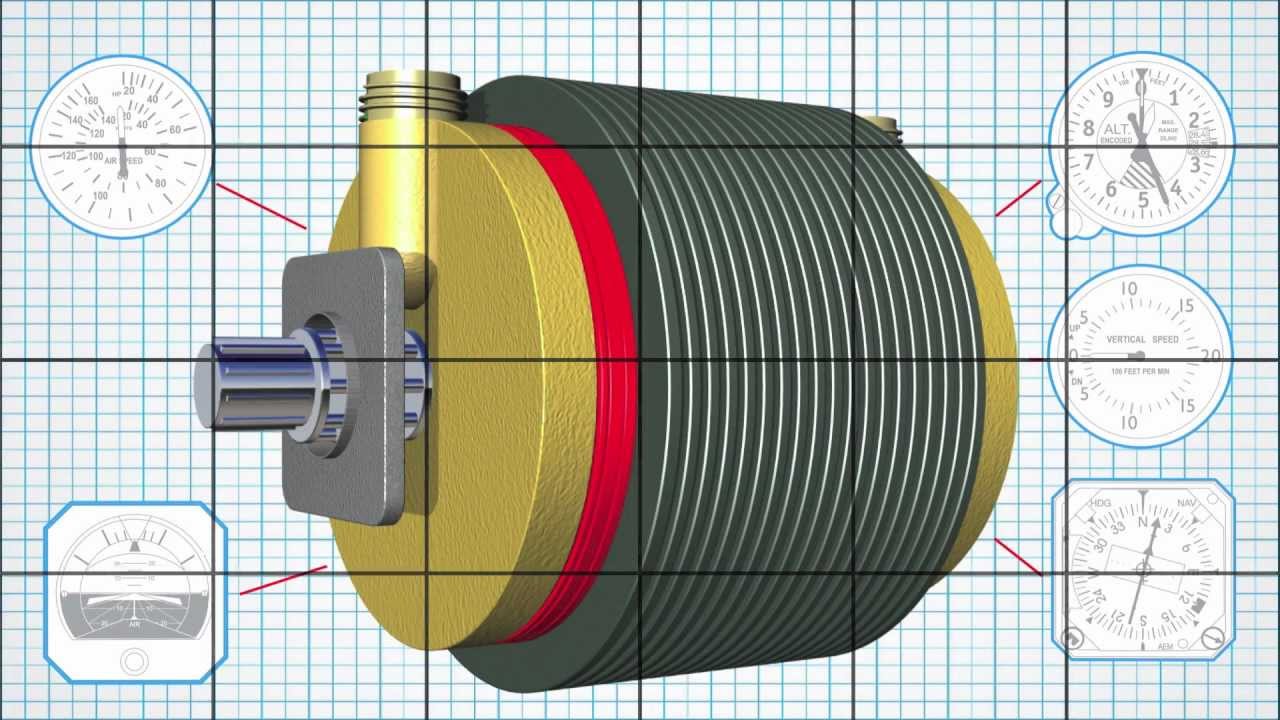

Different vacuum pump diagrams represent various types of pumps, each with its unique mechanism. Rotary vane pumps, for example, utilize rotating vanes within a cylindrical housing to displace air. Diaphragm pumps, on the other hand, employ a flexible membrane to create the pressure differential. Understanding these variations is essential in selecting the right pump for a specific application.

Understanding the workings of a vacuum pump offers several benefits. Firstly, it enhances troubleshooting abilities, allowing for quicker identification and resolution of problems. Secondly, it informs maintenance practices, maximizing the lifespan of the equipment. Thirdly, it empowers users to select the appropriate pump for a particular task, optimizing efficiency and performance.

Numerous online resources, textbooks, and even specialized apps provide detailed information on vacuum pump functionality, including interactive diagrams and simulations. These resources can be invaluable for gaining a deeper understanding of vacuum technology.

Advantages and Disadvantages of Different Vacuum Pump Types

While a detailed table is beyond the scope of this format, generally, rotary vane pumps are known for their robust construction and high vacuum levels, but can be noisy. Diaphragm pumps are quieter and better suited for corrosive gases but offer lower ultimate vacuum levels. Scroll pumps are oil-free and provide good vacuum, but are more expensive.

Best practices for working with vacuum pumps include regular oil changes, leak detection, and proper storage. Understanding the specific requirements for different pump types is vital for maintaining optimal performance and longevity.

Real-world applications of vacuum pumps include freeze-drying food, creating thin-film coatings, and assisting in medical procedures. Understanding how these pumps operate in diverse contexts underscores their importance in modern technology.

Challenges related to vacuum pumps can include leaks, contamination, and performance degradation. Solutions include regular maintenance, proper sealing techniques, and component replacement.

FAQs about vacuum pumps often center on troubleshooting, maintenance, and application-specific queries. Addressing these questions is crucial for ensuring efficient operation and problem-solving.

Tips for effective vacuum pump operation include regular inspection, proper lubrication, and careful handling to prevent damage. These practices can significantly extend the lifespan of the equipment and ensure consistent performance.

In conclusion, understanding how a vacuum pump works, especially through the aid of a diagram, is crucial for anyone working with this versatile technology. From the basic principles behind creating a vacuum to the intricacies of different pump types, this knowledge is essential for troubleshooting, maintenance, and selecting the appropriate pump for a given application. The benefits are numerous, including optimized performance, enhanced longevity of the equipment, and the ability to effectively address challenges that might arise. By grasping the fundamentals of vacuum technology, you can unlock its full potential and contribute to the continued advancement of this vital field. Explore the resources available, delve into the diagrams, and uncover the power of the vacuum pump. The world of vacuum technology awaits, offering a fascinating journey of discovery and innovation.

Unlocking the potential of bulk seed potatoes your guide to 50 lb bags

Embarking on your holistic wellbeing expedition

Hvac vacuum pump manifold rental your ultimate guide